Wire EDM in Europe

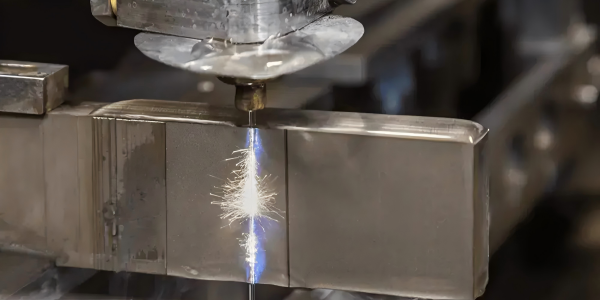

We supplies wire cut EDM CNC machine to distributors and machining workshops in Europe.Our machines are mainly used for mold manufacturing, tooling production, and precision part machining.

European manufacturing is characterized by strict precision standards, rigorous compliance requirements and high-end manufacturing scenarios. Whether it is the micron-level processing of aerospace components, the biocompatibility adaptation of medical implants, or the high-stability production of precision molds, all these places demands on cnc wire erosion machine that exceed those of the ordinary market.

We have been deeply engaged in the European market for many years. Based on our core advantage in standardization, we have developed customized edm wire cutter machine solutions for European customers, taking into account compliance, accuracy and efficient operation and maintenance.

Typical application scenarios:

Aerospace: Precision processing of aircraft engine blades and landing gear components; Medical field: Precision forming of titanium alloy implants and surgical instruments; Mold manufacturing: High-precision injection mold, stamping mold cavity and core processing.

Exclusive advantages for the European market

Service and Support:For overseas customers, we provide remote technical support, online operation training, and long-term spare parts supply to ensure stable machine operation.

(3)

Core demands of the European market and targeted solutions

In the European aviation and medical industries, the precision error of component processing is required to be controlled at the micrometer level, and it is necessary to ensure that there is no deviation during long-term continuous operation.

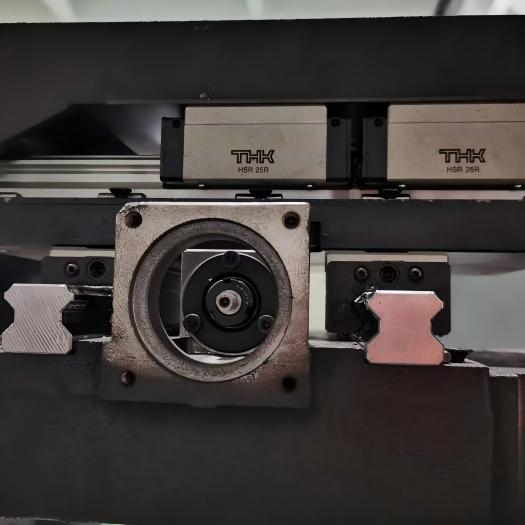

Our wire edm cutting machines are equipped with standardized electrical configurations, featuring internationally certified high-precision guides and control systems. During operation, they do not require frequent calibration and can continuously output stable accuracy, making them perfectly suitable for high-end processing scenarios such as aviation blades, medical screws, and precision mold cavities.

The EU CE certification and electrical safety standards (EN standards) are hard barriers to entering the European market.

All of our CNC EDM spark erosion machines have passed the CE certification. The electrical configuration fully complies with the EU electrical safety regulations, avoiding compliance risks from the design source. There is no need for customers to make additional investments in modification.

It can reduce the repetitive testing and certification of products in the European market, lowering the trade and time costs of enterprises.

In Europe, labor costs are high, and the downtime losses caused by electronica spark erosion machine failures are significant.

Relying on our standardized remote support system, European customers can enjoy technical support in both Chinese and English, simple operation training, and easy-to-understand teaching documents and videos.