Precision High Speed CNC Wire Cut EDM

BQ CNC wire EDM reposition accuracy ±0.003mm, max cutting speed 300mm2/min, machine travel from 400 x320mm to 2000x1500mm, the control system is BQ own research and developed.

- System adopts advanced pulse power and anti-electrolysis power technology

- Win10 operation system, dual CPU design, BQ control system

- THK/PMI/HIWIN guideway and ball screw, NTN/FAG bearings

- Mitsubishi or Panasonic servo, 5 -axis digital display

- Z axis adopts linear guideway, motor control with memory function.

- When cutting taper, only need to input workpiece height, it can calculate automatically.

What work can be done by WEDM?

Wire Cut EDM can be used for machining mold and tools with complex holes and cavities. Processing all kinds of hard and brittle material, such as hard alloy and hardened steel. Machining deep and fine holes, deep grooves, narrow seams and thin slices. Processing all kinds of forming tools, thread gauge and measuring tools. As long as the material is conductive, it can be processed with wire cut EDM.

Comparing with traditional cutting, wire cut EDM process workpiece by erosion the metal and remove the waste. It doesn’t impose any force on the workpiece, so it is a high precision machining.

High Precision Molybdenum Wire EDM

XYUVZ 5 axis numeric control with the function of automatic edge finding, automatic center finding, etc. 5 axis digital display, accurate to Micron, 6 coordinate system for emergency cutting.

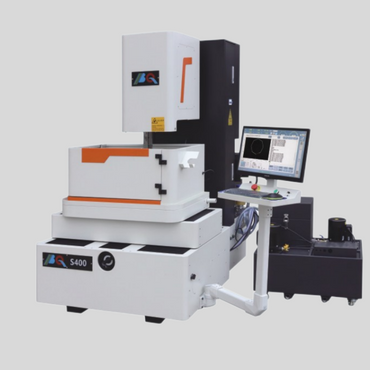

BQS400 is an integrated machine, it adds a handle for users to move the worktable manually, or it can be moved automatically. XY servo driven.

BQ400 is a high accuracy wire cut EDM, XY is Mitsubishi servo, XYUVZ are all linear guideway, high precision ball screw. Panasonic inverter.

BQ500 is one of the best sales machine with Mitsubishi servo. XYUVZ 5 axis numeric control. XYUV 4 axis simultaneous control.

BQ630 machine full travel reposition accuracy is +-0.003mm, max cutting speed 300mm2/min. PMI/HIWIN linear guideway, ball screw.

BQ800 is a new design integrated wire EDM machine, max load 1400kg, the thickness of workpiece can be extent to 500mm, best Ra 0.7 um.

BQ1063 is a large travel wire cut EDM machine, XY travel 1050x 650mm, full travel reposition accuracy is 0.005mm. Mitsubishi servo for XY.

6 Axis Molybdenum Wire EDM

BQY series is new launched machine, it adds W axis for adjustable servo wire tension, to make sure the moly wire work at a constant tension during machining. Minimize the wire loss in full extent.

Large Wire EDM Machine

Economic Wire Cut EDM Machine

BQ System Features

System can memorize machining status automatically when power off, and continue to process when power on.

Workpiece placement do not need to calibrate, after setting AR angle, it will move and process according to the set angle.

Only need to input workpiece height, the system can calculate and finish tapper cutting automatically.

During machining, it can set offset value according to wire loss, do not need to stop current machining.

5 axis full travel precise positioning, coordinate display accurate to micron, reposition accuracy 0.003mm.

Automatic center finding by one key, do not need to record the coordinate value when use spark center finding.

Remote control box can set reference zero point and half-way by one key. XYUVZ 5 axis display.

Tracking and calculate cutting position in real time by software algorithm to ensure precise cutting.

BQS400-One of The Best Sales

BQS400 wire EDM is launched aiming to step motor users, comparing with traditional DK series machines, it adopts 5- axis high precision linear guideway for transmission, XY equipped with servo motor to realize high cutting accuracy and fast jump. Reposition accuracy is less than 3um. First cutting speed 9000-11000mm2/hour.

BQY Series -6 Axis Full Servo Control

BQY series are the high configuration wire cut EDM machine, based on XYUVZ 5axis, it adds W axis for servo wire tension. It has BQY400, BQY500,BQY630 models. It is integrated design, compact and space saving, the full travel machining accuracy less than +-0.003mm with fast cutting speed.

BQ Series -High Precision Wire Cut EDM

BQ Series wire cut edm is separated design, equipped with PMI/HIWIN linear guideway, high precision ball screw, the reposition accuracy is 0.003mm, the cutting is fast, it can bring customer high machining efficiency, this machine is widely used in mold, automotive industry.

Strict Components Inspection

We import ZEISS CMM equipment to inspect the components before assembly, bearing block, motor base, column, machine bed, worktable and other important parts are inspected by ZEISS device. The parallelism, perpendicularity, coaxiality less than 0.01mm, then can be installed.

Accuracy Within 5um after Using 7 Years

After using 7 years, the machine accuracy can keep within 5um. Why BQ wire EDM can achieve this excellent performance? We reply on high precision components, accurate assembly technic and intelligent control system. The main transmission parts are well-known brands from Japan, Germany.

Leading Level Assembly Capacity

Our factory assembly capacity is in the leading level of the industry, 20,000m2 constant temperature assembly line, minimize components tolerance due to thermal change during assembly in the max extent. Professional assembly technician with rich experience, control each procedure strictly to ensure assembly accuracy.

Self-owned Machining Workshop

The only one wire EDM manufacturer in China has own machining workshop for components machining. We introduce OKUMA equipment from Japan, horizontal machine center, gantry machine center, high precision grinding machine, and other advanced equipment to ensure excellent quality in large scale production.

HT300 Body Cast with Two Times Heat Treatment

BQ private customized casting introduce international advanced concept, the same casting supplier with many world well-known brand, such as Okuma, Makino, Mitsui.

Use wood and iron mold to make sand mold, and through twice tempering heat treatment to relieve stress.

The casts are through many precision inspections, grinding, anti-rust treatment, physical and chemical analysis, then accepted.

When casts arrive our factory, they are coarse processed by gantry machining center, and put outside for natural aging at least 8 months, keep machine stability without deformation.

With BQ Molybdenum Wire EDM You Will Get High Accuracy, High Cutting Efficiency

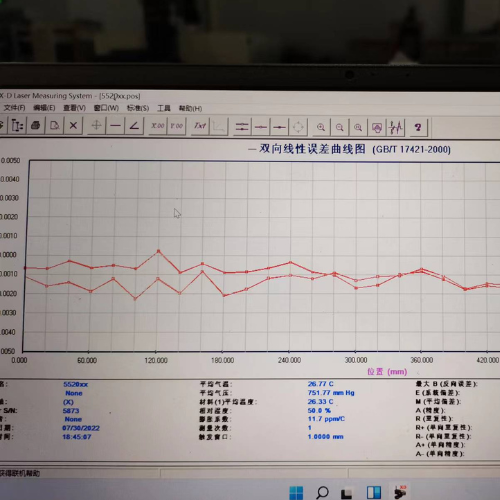

BQ wire EDM performance is stable, we can see from the graph, the accuracy is about 2um during full travel test. Stability is one of the most important factors for machines.

We have large size wire cut EDM machine to process extreme height workpiece. The photo is BQ1612 machine cutting 800mm height parts. The max workpiece can be customized as you need.

BQ wire EDM is a fast cutting efficiency machine, first cut speed 9000-11000mm2/hour, the second cut is about 6500-7000mm2/hour, normal working current is 5.6-6A.

Batches of Machines Send to Customers

- Gallery

Related Product

Would Like to Know More

We have professional sales and technicians to answer your any questions about machines, delivery, business, send us email now, you will get reply soon.

Yes, our international market is in developing, we are glad to meet a powerful and reliable partner for long term cooperation, if you interested, please send your company information to our email.

For exclusive agent, we have requirement about the sale quantity in a period, as well as the service ability. If after a period of cooperation, both are ok, we will authorize exclusivity to you.

It is 30% down payment before production, 70% before delivery.

We usually use EXW, FOB, CIF, CFR as customer need. We have professional forwarder to ship the machine to any countries.