Why Customer Choose BQ Wire Cutting EDM Machine?

- Win10 System with BQ control System(own R&D), dual CPU

- HT300 Casting Machine Body, two times heat treatment

- 5 axis digital display and Z axis motorized freely drive up and down

- Pulse and anti-electrolytic power supply

- W axis servo for constant wire tension

- Mitsubishi servo for XY, XYUVZ 5 axis servo

- THK / HIWIN /PMI high precision linear guide way

- THK / HIWIN /PMI high precision ball screw

- NSK, Japan /FAG, Germany bearings

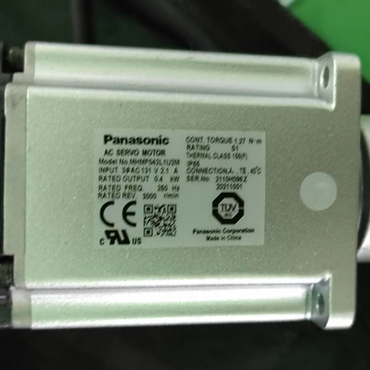

- PANASONIC converter ( Japan Panasonic )

- PHILIPS Industrial Computer

- Automatic center lubrication system

Creating Value For Customer

BQ wire cutting EDM machine sales growth rapidly in both domestic and overseas market, we not only produce machine but also keeping innovation and research, striving to create value for customer constantly. The stable performance, fast cutting efficiency, superior configuration, on time delivery, professional service all makes BQ wire cutting machine be the leading supplier in EDM industry.

Annual sales more than 3000 sets, 20000 square meter manufacturing base, the second phase factory are in construction now.

We welcome customers to visit our factory to inspect machines in site. Contact us for more details, you will get reply within 24 hours.

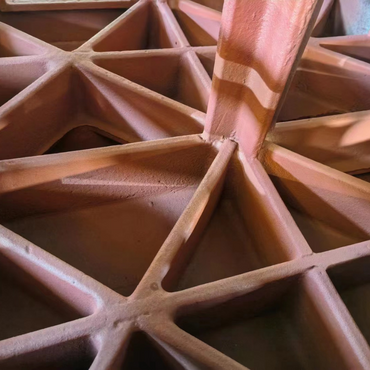

Machine Body Cast

The HT300 body cast adopts resin-sand technology, two times high temperature heat treatment, at least 8 month natural aging, to prevent deformation effectively. Cast is the bone of the machine, if not strong enough, it will be in powder form, the chips of our wire EDM body cast are all in metal pieces.

BQ Wire Cut EDM Configuration

BQ wire cut EDM are high configuration, all main parts are from world well-known brand. Produce high quality machines for worldwide customers.

Welcome Customers To Visit Our Factory

- Factory Gallery