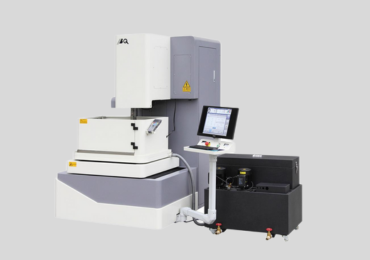

BQ Wire EDM System Function

Mirror processing, taper cutting, scaling

Up-down abnormity cutting, program editing

Single stage machining, 4-axis linkage cutting

Wire radius auto-compensation, wire speed adjustable

Simulation check, machining condition auto-change

return half-way, graphic real time tracking

Pitch correction, hole center finding, edge finding

Return origin point or pause point when machining

Unmanned processing (power off after processing)

Subprogram call, revise offset during machining

- Advantage-1

- Advantage-2

- Convenient Taper Cutting

1. Support remote control, status monitoring and file transfer based on WLAN.

2. Remote control box can set reference starting point and halfway, 5 axis digital display.

3. 5-axis with whole travel precise positioning, coordinate display accurate to Micron.

4. Anti-electrolysis technology making the workpiece cutting more precise.

5. 6 coordinates system. It can memorize the current cutting coordinate, for users to switch any emergency workpiece cutting.

6. Convenient files editing interface, supporting analog simulation of NC files

7. Support multiple reverses cutting, users can choose any program to reverse cut.

8. AR function. The placement of workpiece do not need calibrating, the angle can be determined through two benchmark holes, after setting the AR angle, the moving and machining will proceed as the angle.

9. Power-off protection function. It can memorize machining status automatically when sudden power off, and continue to process when the power supply recovers

10. Tracking and error prevention function. Closed-loop software algorithm, it can recognize cutting position in real-time to prevent error cutting, ensure work piece safety.

11. New offset function. During machining, users can set new offset according the moly wire loss, do not need to stop current machining

12. Set suspension point. During processing, just click the code to set or cancel the suspension point.

13. 2D、3D graphics display function. Work piece graphics can be zoomed and rotated freely, easy to check.

14. After programming, the offset can be modified at any time, does not need to be reprogrammed.

15. if the machining is interrupted, does not need to find the origin point after turning on, it can continue to process without any position change.

16. Support absolute encoder, the position change caused by vibration after power off, it can automatically return to the original point after power on.

17. If the threading hole in the wrong position, leads to short circuit, user can move it to the right position, it can back to the starting point to finish cutting

18. Back to suspension point. It can memorize the suspension point automatically during cutting, users can move 5-axis arbitrarily, then back to the suspension point by one key. This is convenient for changing moly wire and take out the waste.

19. Automatic center finding. Find center by one key, spark center finding, do not need to memorize the coordinates, it can back to center automatically.

20. Jump function. It can jump between any hole position or any stage.

21. Ignore function. You can choose any program to cut from the current position.

22. Pitch and reverse gap compensation function. After using many years, if the ball screw precision has deviation, it can be corrected through the pitch compensation.

1. Simply enter the workpiece height when cutting taper, the system will calculate and finish taper cutting automatically. Even Z-axis was moved, the taper degree will not change.

2. Z-axis adopts high precision linear guideway, it can memorize machining position automatically.

3. XYUV axis all adopt direct-connect motor control, using the imported high precision linear guide, which can improve the taper cutting accuracy effectively.

4. Z-axis lifting system is driven by motor, and controlled by remote control box, it can go up and down freely, do not need to dismantle the moly wire, this is convenient for taking out the waste.