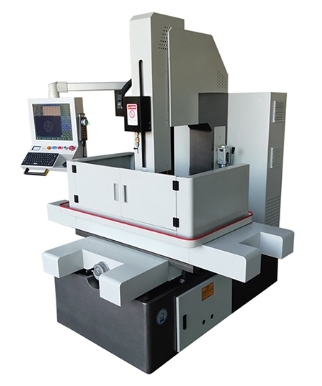

Precision High Speed CNC450 EDM

Z-axis motor:AC deceleration motor, lifting speed is fast, high sensitivity.

XY axis motor: AC servo motor drive, advanced non-damping protection.

Anti-interference touch industrial control display screen:High resolution, anti-electromagnetic interference.

Electrode replacement: The Z-axis can be automatically raised to a certain position, and then the electrode can be manually replaced.

It can save the information of multiple machining holes, avoid frequent input after power failure, and can re-edit and save the original machining.

Advantages of EDM Drilling Machines

EDM drilling machine is a kind of special machine tool that utilizes the principle of electric spark discharge to realize material processing, mainly used for precision hole processing of high hardness and hard-to-cut materials (such as hardened steel, hard alloy, ceramics, etc.). Its working principle is to generate high temperature through the pulse discharge between electrode and workpiece to make the material locally melted or vaporized, so as to realize the contactless etching processing.

The equipment is suitable for processing deep and small holes, shaped holes, slanted holes and other complex structures, and is widely used in mold manufacturing, aerospace, medical equipment and other fields. It is characterized by high processing precision, not limited by material hardness, and can process special structures that are difficult to deal with by traditional mechanical methods.

CNC 3axis digital control small hole machine

Digital display control, intelligent and stable operation, automatic replacement of brass tubes

The Z-axis can be automatically raised to a certain position, and then the electrode can be manually replaced.

CNC630 is a high-precision drilling machine with automatic edge finding and automatic center finding.

CNC800 is a large stroke CNC machine that can process some large workpieces.

Semi-automatic Drilling Machine

With one-touch piercing function, cutting from the beveled side, equipped with AC servo drive

The DZ703 has a limit function: it automatically rises to the top when meeting the lower limit.

It has a fixed depth function that adopts an encoding disk for accurate and reliable counting operations.

Intelligent tool lifting function: set the workpiece thickness and punching, one-key processing end.

Adopts encoder/player architecture, CNC encoder realizes the management of CNC process database files.

Adopts tungsten steel wear-resistant plate and multiple waterproof structure.

It can clearly track and display the processing trajectory, and completely solve the problems of black screen.

Set the workpiece thickness and punching, one-key processing end, automatically lift to the surface of the workpiece.

It can save the information of multiple machining holes, re-edit and save the original machining after power failure.

During multi-hole processing, it can forcibly exit the processing of the current hole and switch to the next hole.

The Z-axis can be automatically raised to a certain position, and then the electrode can be manually replaced.

It can effectively realize programming and control in time-sharing mode; real-time tracking processing trajectory.