Military and Defense

Application Advantages

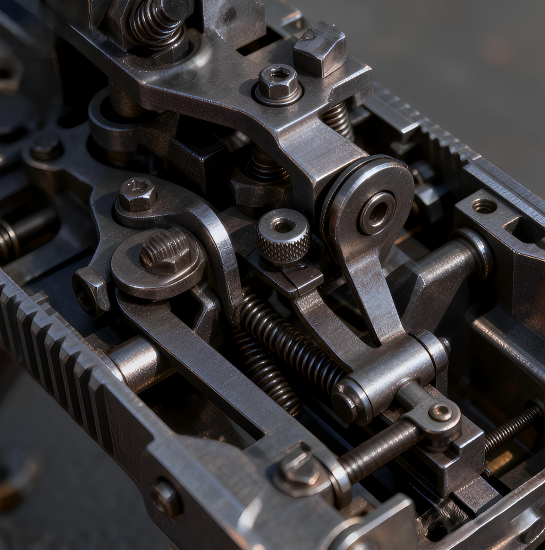

EDM spark erosion machine‘s applications span multiple categories of critical defence equipment: in firearms manufacturing, machining core components such as bolt assemblies and firing mechanisms to ensure shooting accuracy; in armoured vehicles, processing armour connection structures and sighting assemblies to enhance protection and mobility; in aerospace defence equipment, machining fighter jet engine blades and missile guidance components to influence propulsion and control precision. and in naval vessels, machining components for propulsion and radar systems to safeguard long-range navigation and detection capabilities. Additionally,wire cut edm machine enables the production of specialised tooling and moulds to ensure consistent quality in mass production.