Mechanical Machining

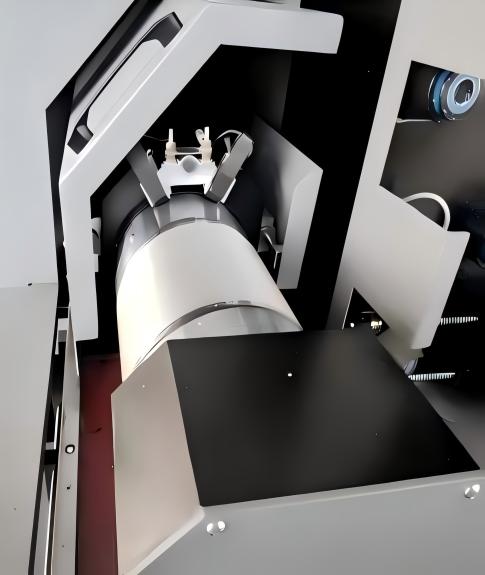

Conventional machining relies on physical cutting tools, which often fail when processing ultra-hard or heat-treated materials.Wire cut edm machine operates completely tool-free, utilizing electrical discharge technology to erode workpiece material directly.Automatic wire cutting machine easily handles hardened tool steel, tungsten carbide and high-strength alloys that traditional equipment cannot process. This non-contact method avoids tool wear and workpiece deformation, excels at shaping complex contours and micro-features, and cuts down on tool replacement costs and production downtime. It’s a game-changing solution for high-precision, efficient mechanical machining.

EDM wire cutter machine equipment is not merely a high-performance processing apparatus; it has propelled the advancement and transformation of the mechanical processing industry. Its processing advantages have overcome numerous challenges inherent in traditional machining methods, while its extensive range of applications caters to the diverse demands of the sector. This technology not only provides robust support for enterprises seeking to enhance production efficiency and strengthen core competitiveness, but also injects sustained momentum into the mechanical manufacturing industry’s transition towards high-end and intelligent production. Consequently, it has become an indispensable core piece of equipment within the modern mechanical processing domain.

Application Advantages

The core advantage of cnc spark erosion machines lies in their resolution of traditional machining challenges and adaptability to processing requirements. Compared to conventional cutting methods, it employs a non-contact electrical discharge machining process. When processing high-strength, high-hardness specialised materials, it can maximise the retention of the material’s inherent properties. Underpinned by CNC systems, edm spark erosion machine handles irregular contours and minute structures. Whether executing complex curved surfaces, or high-precision hole positioning, it achieves stable forming. Furthermore,programming modes enable rapid switching between machining schemes, perfectly addressing the multi-variety, small-batch, and customised production characteristics of the mechanical processing sector.

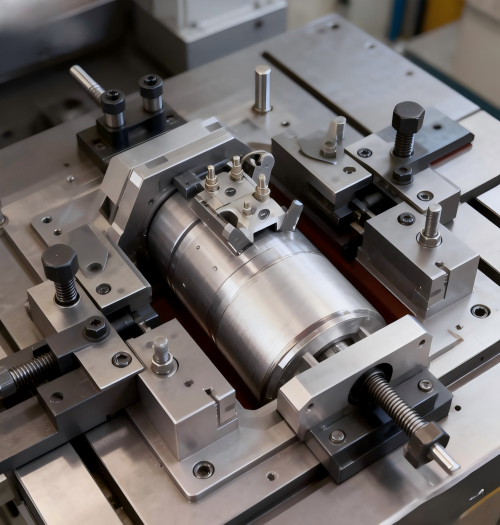

Through these core strengths, the application scenarios of wire spark erosion machine now extensively cover multiple core domains of mechanical processing. In general machinery manufacturing, it delivers precision machining services for fundamental components ensuring the stable operation of various equipment. Within precision machinery and automation, its high-precision machining capabilities support the production of critical components for automated production lines,directly enhancing the operational accuracy and response speed of automated equipment. Within tooling and mould manufacturing,wire edm cutting machine enables precise machining of hardened tool steel, efficiently producing forming dies like stamping dies and injection moulds.