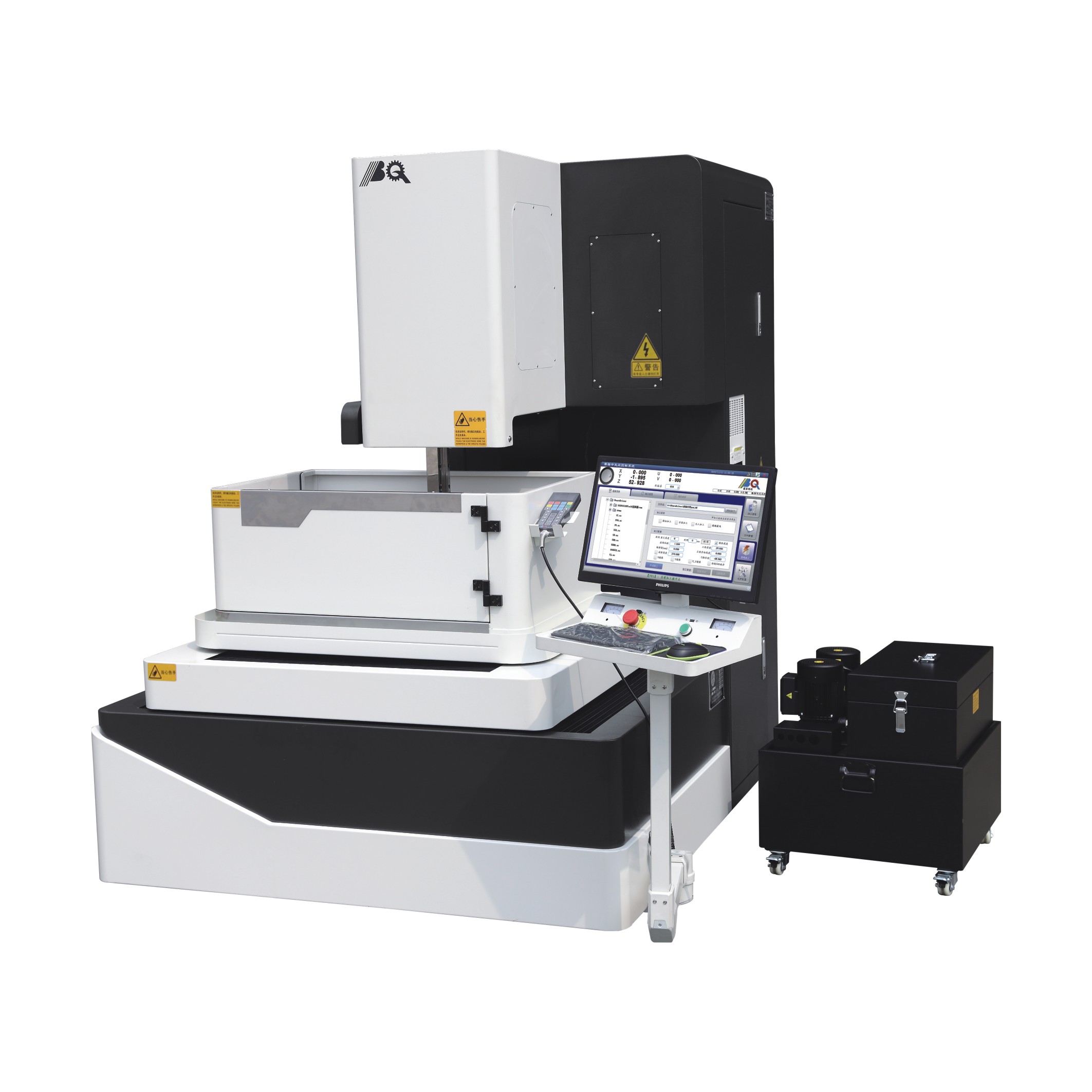

The first is the CNC machine design

This is the soul of machine precision. Japanese machines look nothing special, but they are high-precision and durable. High-precision CNC machines have a perfect detail design.

The second is machines castings

Casting is the skeleton of the machine, it is the key to bear the cutting torque force and disperse vibration, machine casting is the foundation of machine stability. For high-precision CNC machines, without good castings, even the best spindle ,best guideway and ball screw, the accuracy will lost after one year.

The third is that the system

System can determine the accuracy of the CNC machines. Conventional imported systems include Fanuc, Mitsubishi, Siemens, and Heidenhain, most of the machines use Fanuc. FANUC systems are widely used in gantry, horizontal, vertical, lathes, sheet metal machines and even robots.

The machine accuracy is the accurate level of the main components shape, mutual position and relative motion. Including geometric accuracy, transmission accuracy, motion accuracy, positioning accuracy and accuracy retention.

In the design stage, we enhance the machine accuracy from accuracy allocation, selection of components and materials. Our machine casting is the same supplier with Okuma, Makino, Mitsui.