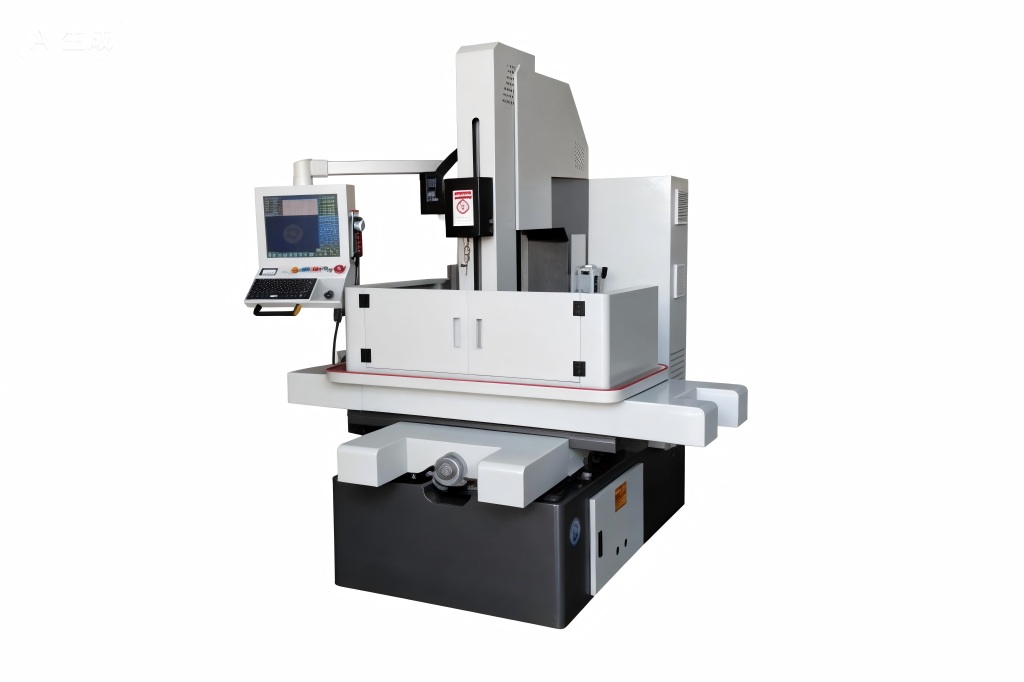

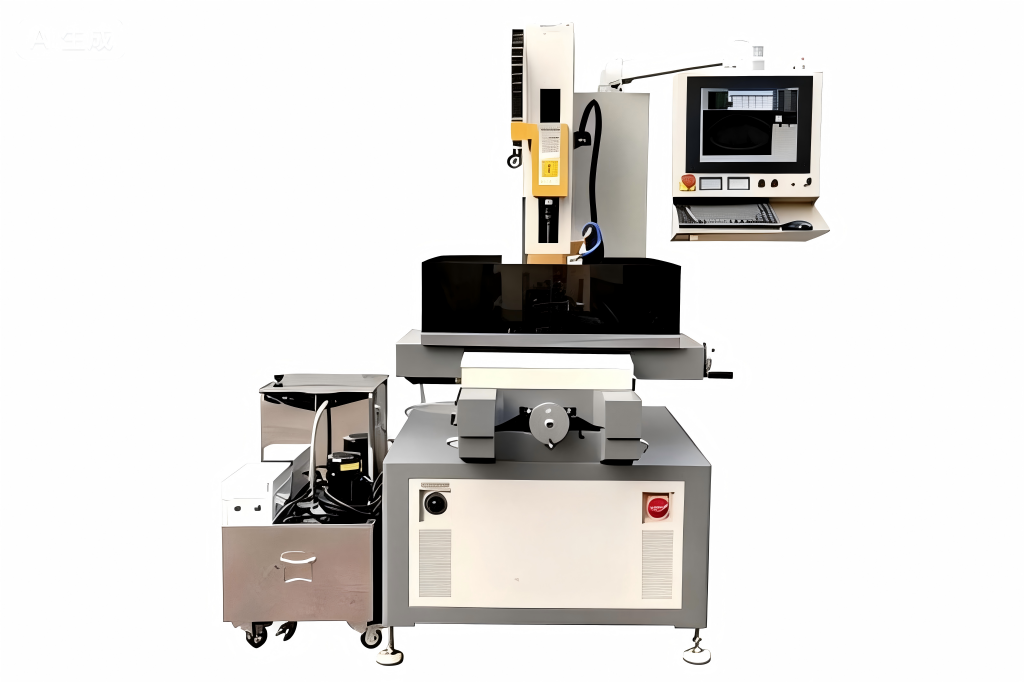

CNC Drilling EDM Machine

As a leading Chinese supplier of EDM small hole drilling machine with years of specialised expertise, our high-performance drilling ED machine delivers exceptionally rapid cutting speeds to enhance production efficiency.

Beyond machining deep holes and small apertures (Φ0.1mm–3mm), it excels in precision processing for aerospace components, mould parts and precision tools, maintaining consistent performance across conductive materials including stainless steel, hardened steel, copper, aluminium and cemented carbide.

The EDM deep hole drilling possesses the capability to process complex hole geometries, enabling precise machining of deep small holes, irregularly shaped holes, and inclined holes. The core deep hole drilling technological advantage of this equipment lies in its exceptionally high machining precision, which is not constrained by the hardness of the workpiece material. Hole drilling EDM machine fulfils specialised structural machining requirements unattainable through conventional mechanical processing methods.

High Precision Electronica CNC Edm Drilling Machine

- Best drilling edm machine system uses a touch screen industrial computer, fast running speed, and can process massive amounts of data at the same time.

- Highly automated for cost reduction and efficiency gains:

Supports multi-station automated machining, completing multiple hole operations with a single clamping; equipped with breakpoint memory, penetration detection and automatic chip removal functions, enabling extended unattended operation; produces burr-free hole walls post-machining, eliminating secondary polishing and deburring processes to shorten production cycles.

CNC EDM drilling machine can save the information of multiple machining holes, avoid frequent input after power failure, and can re-edit and save the original machining.

During multi-hole processing, super drill EDM can forcibly exit the processing of the current hole and switch to the next hole for processing.

CNC EDM drilling machine is suitable for Φ0.1(or above) electrode tube drilling, super thick workpiece within 250mm, tungsten steel, aluminium, AK80 and other super hard or special materials.

Super drill EDM machine has automatic centering, automatic edge finding, and automatic finding of the surface of the workpiece.

Electronica EDM drilling machine has automatic penetration detection, and depth coordinates can also be set manually.XYZ three-axis precision ball screw, Taiwan HIWIN linear guideway.

EDM small hole drilling machine has the function of segmented processing, which can realize the lamination processing of different materials.

Large CNC Edm Drilling Machine

- Super drill EDM has high-frequency automatic limit function can make the perforated surface without burnt marks.

- Equipped with a computer numerical control (CNC) system, it precisely controls the three-axis movement trajectory of the electrode and discharge parameters (pulse width, current, gap), automatically completing the entire process including positioning, machining, retraction, and chip removal without manual intervention.

EDM small hole drilling’s rotating head of the motor: adopts tungsten steel wear-resistant plate and multiple waterproof structure to ensure the rotating concentricity of the chuck.

Hole drilling EDM is suitable for machining deep and small holes between Φ0.15mm-3mm in diameter on various conductive materials.

Three-axis CNC system: adopts encoder/player architecture, CNC encoder realizes the management of CNC process database files, CAD. G code and other engineering files.

Hole drilling EDM’s digital high frequency: PWM special pulse outlet.High frequency soft start function, machining surface without burrs.

EDM small hole drilling machine has rich data interfaces, the system can directly load and edit data through U disk, network port, and wireless, so as to generate the most reasonable processing route.

EDM small hole drilling machine support X.Y.Z three-axis CNC machining, suitable for flat and arc surface drilling.