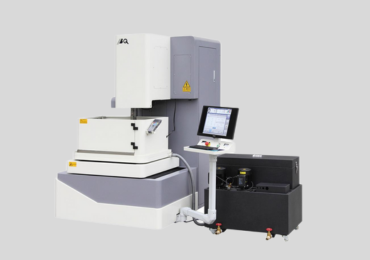

Moly wire EDM is using molybdenum wire as the electrode to erode conductive material. BQ series EDM machine adopt high strength, low lost moly wire to save the machining cost and enhance cutting efficiency.

Molybdenum wire is widely used as electrode wire in fast wire EDM cutting, and brass wire with a diameter of 0.1mm or more is widely used in slow speed wire cutting.

Brass wire is suitable for slow processing, the surface roughness and flatness of processing are better, less corrosion debris adheres, but the tensile strength is poor, the loss is large, the diameter is in the range of 0.1-0.3mm, generally used for slow one-way running processing. Molybdenum wire has high tensile strength and is suitable for fast wire-feeding processing. Therefore, molybdenum wire is mostly used as electrode wire for fast wire-feeding machine, with a diameter in the range of 0.08-0.2mm. BQ series EDM use 0.18mm moly wire.

The diameter of the electrode wire should be selected according to the width of the slit, the thickness of the workpiece and the size of the corner. If processing small molds with sharp corners and narrow slits, thinner electrode wires should be used. If processing large-thickness workpieces or high-current cutting, thicker electrode wires should be selected.