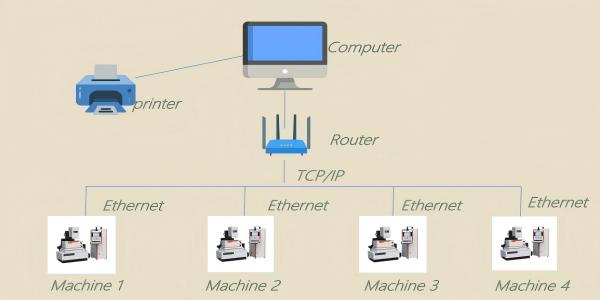

Intelligent production optimization, remote monitoring of CNC machines

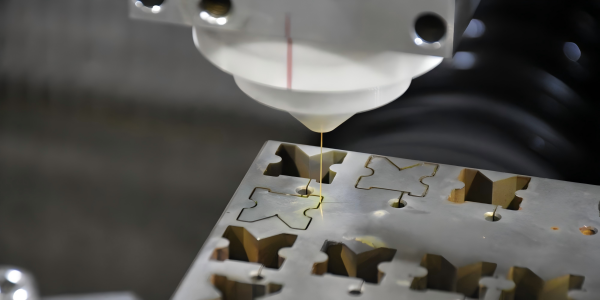

CNC machines are playing an increasingly important role in industrial automation. With the transformation of the manufacturing industry towards automation and intelligence, the traditional monitoring […]

Intelligent production optimization, remote monitoring of CNC machines Read More »