Aerospace Components

Numerically controlled edm wire erosion machine equipment, with its distinctive processing advantages, aligns profoundly with the stringent manufacturing requirements of the aerospace industry. It delivers high-precision, highly reliable machining solutions across multiple domains, including core propulsion components, spacecraft structural elements, and tooling inspection fixtures. This equipment has become a vital technological pillar driving the aerospace manufacturing sector towards ever-greater precision and performance.

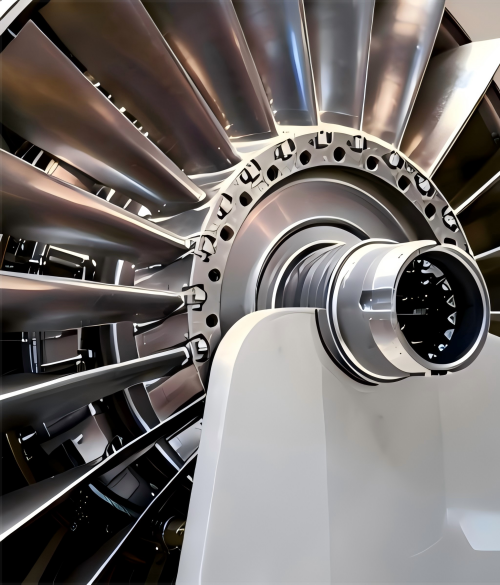

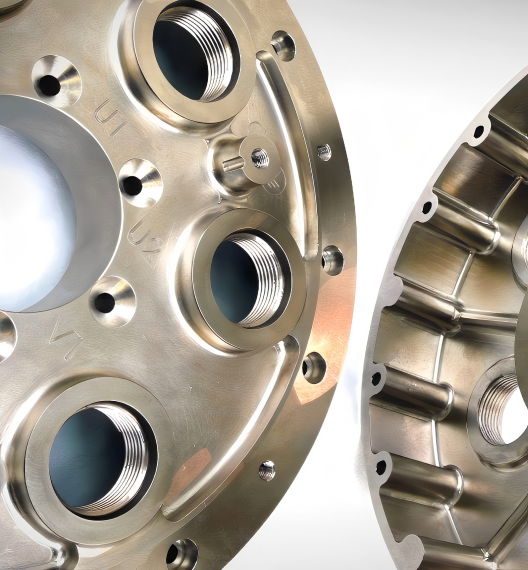

Wire spark erosion machine are widely utilized for manufacturing high-hardness components in the aerospace industry. These machines excel at processing challenging materials such as titanium alloys and nickel-based superalloys—materials that are integral to aircraft engine blades, turbine disks, and critical structural components.

They enable precise, intricate shape cutting that traditional machining methods struggle to achieve, even for parts with complex cavities and thin-walled structures. By delivering consistent, defect-free results,wedm machine ensures the strict quality and performance requirements of aerospace applications are fully met, supporting the industry’s uncompromising standards for safety and durability.

Application Advantages

In the manufacturing of core components for aero-engines, cne wire erosion machine plays an irreplaceable role.Components such as blades, discs, and nozzles feature complex curved surfaces, intricate cooling channels, andthin-walled structures, making it difficult for traditional machining methods to simultaneously achieve precision andpreserve material properties. Through its non-contact electrical discharge machining process, wire electricaldischarge machining wedm equipment precisely cuts such intricate structures without inducing thermaldeformation or physical stresses during machining. This maximally preserves the material’s inherent high-temperaturestrength and corrosion resistance, ensuring the aerodynamic contour accuracy of blades and the assembly precision ofdiscs.

The core advantages of edm wire cutting machines for the aerospace industry also lie in their flexible programming andefficient machining capabilities. Tailored to the aerospace sector’s production characteristics of diverse varieties and smallbatches, its CNC system rapidly adapts to the customised design requirements of different components. This enables theprecise writing and swift debugging of complex machining programmes, significantly shortening product development andproduction cycles. Simultaneously, electronica spark erosion machine‘s stable machining capability for thin -walledand minute components meets the trend towards miniaturisation and integration in aerospace equipment, therebysupporting the technological advancement of high-end aerospace systems.