Wire EDM in Middle East

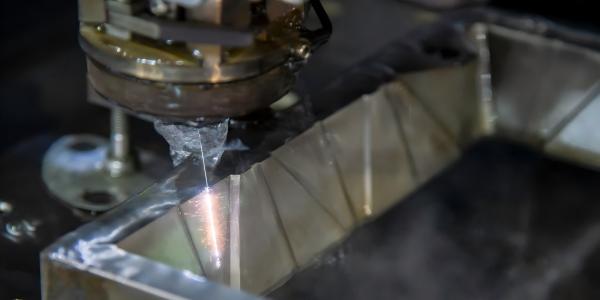

We provides CNC wire spark erosion machines for customers and distributors in the Middle East.The wire electrical discharge machining machines in this market are typically applied in fields such as industrial manufacturing, mold processing, and metal parts processing, where a robust structure and stable operation are required.

The manufacturing industry in the Middle East focuses on fields such as energy (oil and natural gas) and precision machinery. The production environment often faces challenges such as high temperatures, dust, and unstable power grids. At the same time, there are strict requirements for the weather resistance, adaptability, and long-term supply of spare parts of equipment. Combining the characteristics of the Middle East market and relying on the core advantage of standardization, we have created a temperature-resistant and highly adaptable cnc edm spark erosion machine solution, providing stable and reliable processing guarantees for energy and precision manufacturing customers.

Typical application scenarios:

Energy sector: Precision processing of oil and gas valves and wellhead equipment, cutting of core components for new energy (photovoltaic, wind power); Precision machinery: Processing of medical equipment components and precision structural parts for electronic equipment.

Exclusive advantages of the Middle East market

Service and Support:For overseas customers, we provide remote technical support, online operation training, and long-term spare parts supply to ensure stable machine operation.

(3)

Core demands of the Middle East market and targeted solutions

The Middle East region is characterized by high temperatures, dryness and dust, making ordinary equipment prone to problems such as component wear and reduced precision.

Our wire spark erosion machines are equipped with exclusive dust-proof and sealed designs. The electrical cabinets are fitted with constant-temperature heat dissipation systems. The core components are made of high-temperature resistant and wear-resistant materials, enabling stable operation in high-temperature and dusty environments, and perfectly adapting to the harsh working conditions of energy plants.

Valves, joints, sensors and other components in the oil and gas industry need to have high precision and corrosion resistance, and the requirements for processing equipment are extremely high.

Relying on a standardized high-precision control system, the cnc wire cutting machine can achieve precise cutting of complex and irregular parts, with a processing accuracy of ±0.003mm. At the same time, it supports the processing of corrosion-resistant materials such as stainless steel and titanium alloy, meeting the production demands of core components in the energy industry.

In some parts of the Middle East, the industrial foundation is weak, the procurement cycle of spare parts is long, and the after-sales support resources are limited.

We provide on-site or remote bilingual (Chinese and English) technical support through a standardized remote support system to quickly resolve wire edm machine malfunctions. At the same time, a long-term spare parts supply mechanism should be established, with sufficient reserves of core components and rapid delivery to ensure the long-term stable operation of the equipment.