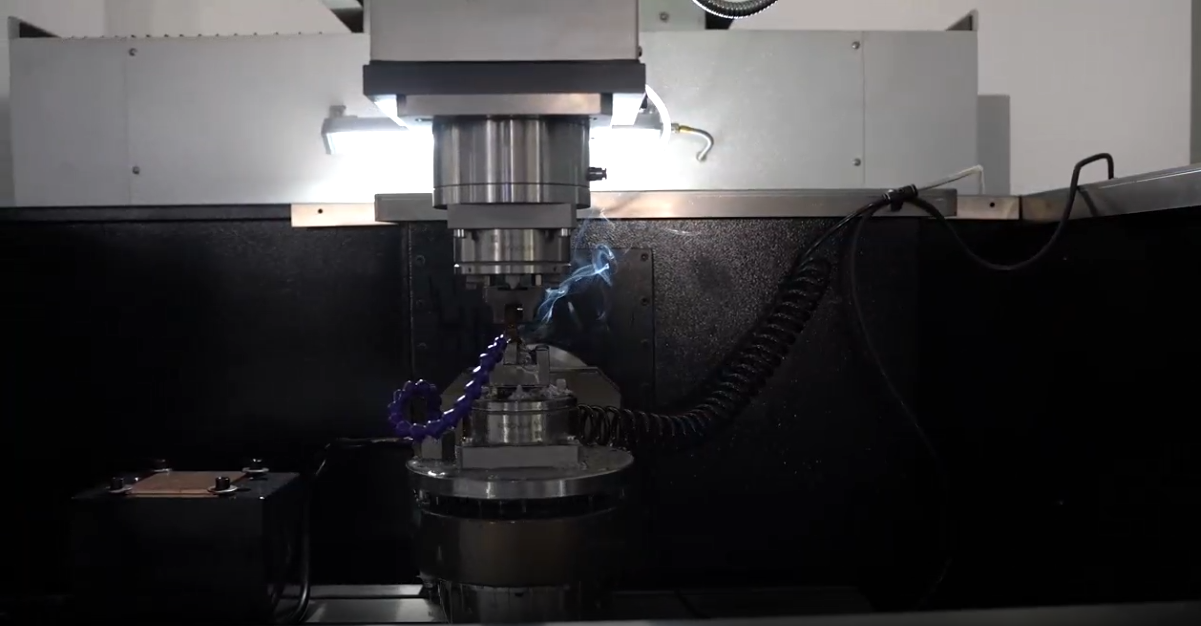

ZNC Die Sinking EDM Machine(Single Shaft)

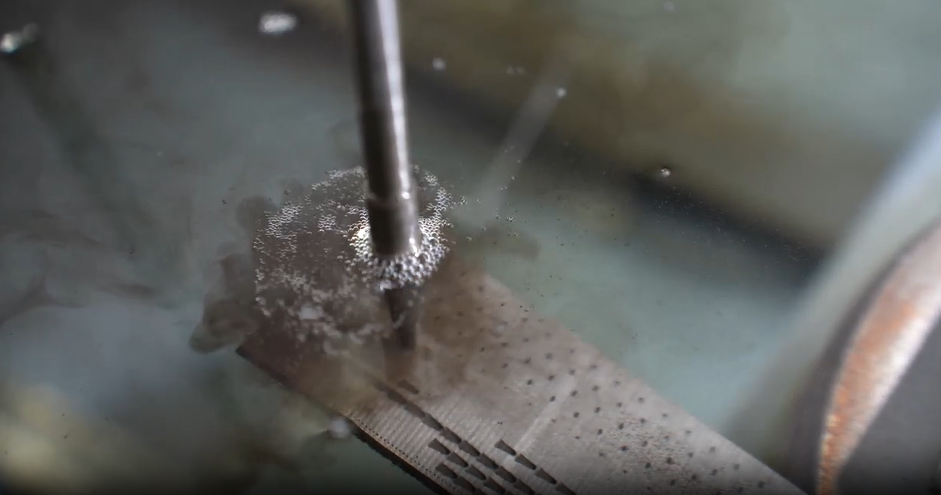

Efficient Machining Capability

- High lifting function for deep cavity machining to improve chip removal efficiency

- Automatic rough-finish parameter matching to simplify operations and ensure precision

Adaptive Process Solutions

- Intelligently matches parameters according to electrode shape and material

- Copper and graphite separation circuit for optimized processing of different electrodes

- Power tube adopts composite VMOS tube for stable output and durability

- Automatic A.R.C anti-carbon deposition inspection device to reduce downtime

Sepcification

- EDM350/450/550/650

| Parameters | EDM350 | EDM450 | EDM550 | EDM650 |

| Worktable size(mm) | 600×350 | 700×420 | 800×500 | 1000×600 |

| X/Y/Z travel(mm) | 350×250×300 | 450×350×(200+200) | 550×450×(250+300) | 650×550×(280+300) |

| Main shaft load(kg) | 50 | 90 | 120 | 150 |

| Distance from electrode plate to tabletop(mm) | 200-500 | 150-550 | 200-750 | 320-900 |

| Axis Resolution(mm) | 0.005 | 0.005 | 0.005 | 0.005 |

| Table Bearing(kg) | 300 | 1200 | 1500 | 2000 |

| Working liquid tank(mm) | 900×560×310 | 1170×650×400 | 1300×750×450 | 1700×1000×490 |

| Electrode loss(%) | 0.2% | 0.2% | 0.2% | 0.2% |

| Max machining current(A) | 50 | 50 | 50 | 50 |

| Surface Finish(um) | Ra0.3 | Ra0.3 | Ra0.3 | Ra0.3 |

| Efficiency (mm2/min) | 500 | 500 | 500 | 500 |

| Machine weight(kg) | 1500 | 1700 | 2500 | 3500 |

| Dimension of machine(mm) | 1500×1400×2450 | 1550×1500×2200 | 1750×1600×2350 | 2100×1800×2500 |