EDM Die Sinking Machine Introduction

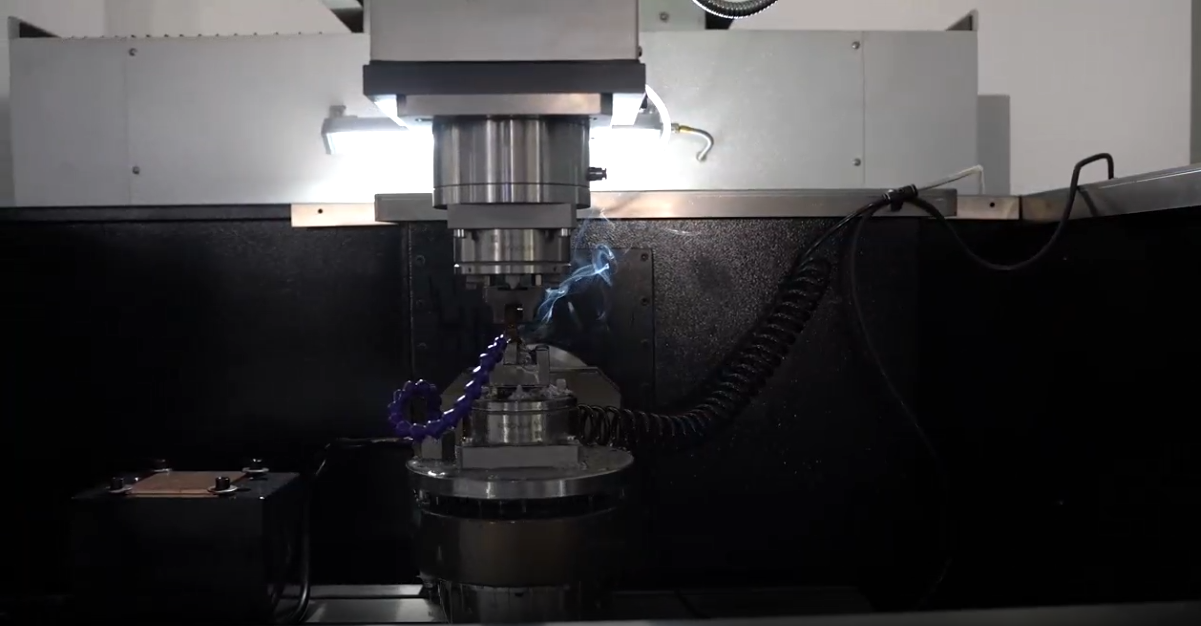

Our CNC EDM forming machines feature high efficiency, low electrode wear, and excellent surface finish. We offer a comprehensive range of models and specifications, including single-axis CNC (ZNC), three-axis CNC (CNC), single-head, double-head, and mirror-finish EDM machines, which have earned a strong reputation in the mold industry.

The future development of EDM forming machines will focus on the direction of 3-axis linkage numerical control (CNC) technology, such as CNC EDM machines. The core development trends include precision enhancement, intelligence, automation, and efficiency improvement of EDM equipment. The key performance of EDM machining lies in its ability to meet strict requirements for dimensional accuracy, profile accuracy, and surface quality.

By adopting advanced machining technologies, EDM machines can achieve mirror-finish machining results and successfully process high-precision mold components used in micro connectors, IC plastic packaging, mobile phones, CD cases, and other products. Therefore, EDM machines will fully drive the further development of existing NC machining technologies and continuously improve the machining accuracy of molds.

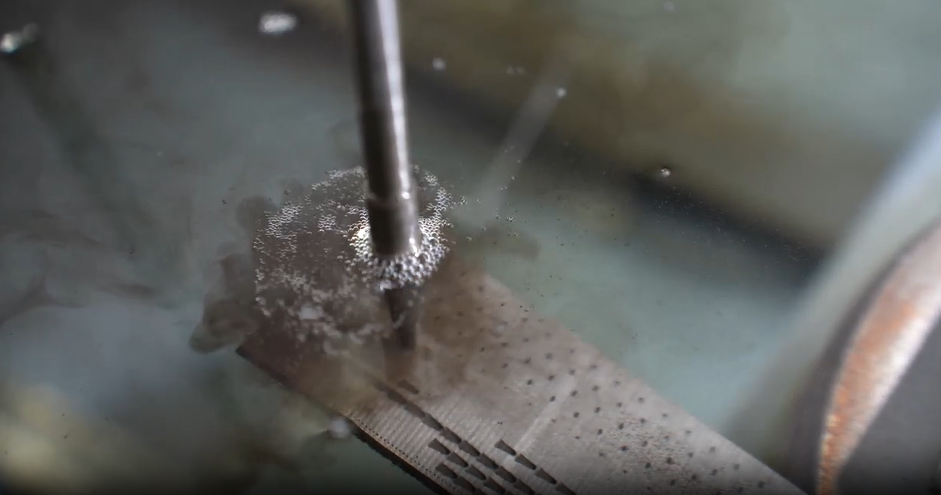

The axis resolution of the machine tools is all 0.005mm, and the surface finish can all reach Ra0.3μm. Such high precision performance can ensure that the processed parts have precise dimensions and good surface quality, meeting the processing requirements with high precision.

The strong load-bearing capacity enables the machine tools to process larger and heavier workpieces, expanding their range of applications.

The processing efficiency is 500mm²/min. While ensuring processing accuracy, it can complete processing tasks with high efficiency, which is conducive to improving production efficiency and reducing processing time costs.